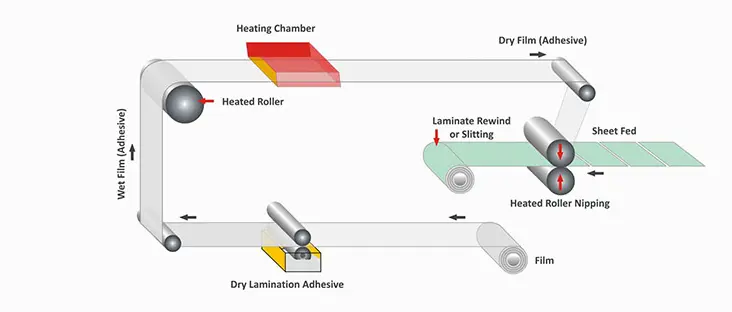

Dry lamination is a common method used for composite plastic films. In this process, different plastic films are bonded together using adhesive. The steps are as follows:

Step 1: Prepare the Plastic Films First, prepare the plastic films that need to be laminated together. These films may have different properties, such as transparency, barrier properties, and heat resistance, to meet specific packaging requirements.

Step 2: Apply Adhesive Use specific equipment to apply adhesive onto one surface of a plastic film. The choice of adhesive is typically optimized based on the materials being laminated and the intended application.

Step 3: Lamination Press the adhesive-coated plastic film against another plastic film to form a composite structure. This process is usually conducted under specific temperature and pressure conditions to ensure a stable lamination.

Step 4: Curing Once lamination is complete, the composite film may require curing under specific conditions to ensure the adhesive fully sets and achieves optimal bonding strength.

Post time: 07-24-2023