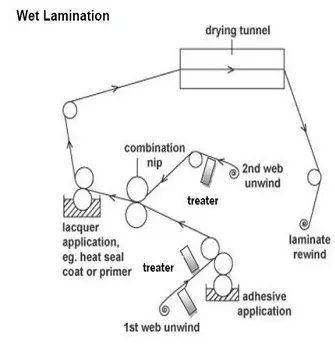

Wet lamination is another common method used for composite plastic films, especially when incorporating paper or fibrous materials. This method involves applying adhesive through coating or impregnation onto a plastic film and then bonding it with other film layers. The steps are as follows:

Step 1: Prepare Plastic Film and Other Materials First, prepare the plastic film and other materials, such as paper or fibers, that need to be laminated together.

Step 2: Prepare Adhesive Prepare the adhesive used for coating or impregnation, ensuring it is suitable for the characteristics and requirements of the composite materials.

Step 3: Coating or Impregnation Coat the adhesive onto the surface of the plastic film or impregnate the plastic film with the adhesive to cover the entire surface.

Step 4: Lamination Press the adhesive-coated plastic film against the other material (e.g., paper or fibers) to create a tightly bonded composite structure.

Step 5: Drying After lamination is complete, the composite film needs to be dried under appropriate conditions to ensure the adhesive fully cures and stabilizes the composite structure.

Post time: 07-24-2023