Unveiling the Secrets of Lamination Packing: Enhancing Packaging with Layered Protection

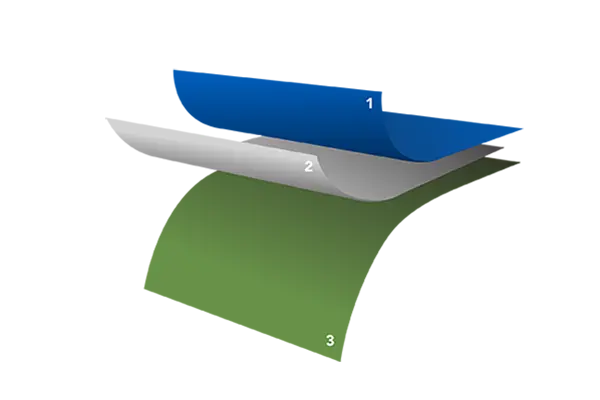

In the realm of packaging, lamination stands as a versatile and widely used technique, combining multiple layers of material to create a durable, protective, and aesthetically appealing barrier for products. This process involves bonding together two or more layers of flexible materials, such as films, foils, or papers, using adhesives or heat. Lamination offers a range of benefits, making it an indispensable tool in the packaging industry.

Delving into the Lamination Process

The lamination process typically involves several steps:

-

Material Preparation: The individual layers of material are carefully selected and prepared for bonding. This may include surface cleaning, pre-treating, and ensuring proper alignment.

-

Adhesive Application: Adhesives, often in the form of liquid films or resins, are applied to one or both of the material layers. The adhesive type and application method are chosen based on the specific materials and desired properties.

-

Laminating Stage: The prepared layers are brought together and passed through laminating machinery, applying heat and pressure to activate the adhesive and permanently bond the layers.

-

Quality Control: The laminated material undergoes rigorous quality control checks to ensure proper bonding, adhesion strength, and surface finish.

Benefits of Lamination in Packaging

Lamination offers a multitude of benefits for packaging applications:

-

Enhanced Barrier Properties: Lamination creates a multilayer barrier that protects products from moisture, gases, odors, and external contaminants.

-

Improved Strength and Durability: The combined layers provide increased strength, tear resistance, and puncture resistance, safeguarding products during handling and transportation.

-

Enhanced Appearance and Printability: Lamination allows for high-quality printing and finishing, creating visually appealing packaging that attracts consumers and enhances brand image.

-

Extended Product Shelf Life: The protective barrier provided by lamination helps to preserve product integrity, extending shelf life and reducing spoilage.

-

Versatility and Customization: Lamination can be customized using a variety of materials, adhesives, and thicknesses to meet specific packaging requirements.

Applications of Lamination in Packaging

Lamination finds extensive use in a wide range of packaging applications:

-

Food Packaging: Lamination is widely used in food packaging, protecting foods from spoilage, contamination, and external factors.

-

Pharmaceutical Packaging: Lamination is crucial for pharmaceutical packaging, ensuring the integrity and stability of sensitive medications.

-

Cosmetic and Personal Care Packaging: Lamination enhances the appearance and durability of cosmetic and personal care packaging, preserving product quality and extending shelf life.

-

Industrial Packaging: Lamination is employed in industrial packaging to protect products from harsh environments, such as chemicals, solvents, and extreme temperatures.

-

Flexible Packaging: Lamination is a cornerstone of flexible packaging, providing a lightweight, durable, and protective barrier for a wide range of products.

Conclusion

Lamination has revolutionized the packaging industry, providing a versatile and effective means of enhancing product protection, extending shelf life, and creating visually appealing packaging. As consumer demand for sustainable and eco-friendly packaging grows, lamination continues to evolve, incorporating recycled materials and biodegradable adhesives to minimize environmental impact. With its adaptability and ability to meet diverse packaging needs, lamination will undoubtedly remain an essential tool in the packaging industry for years to come.

Post time: 11-28-2023